Services

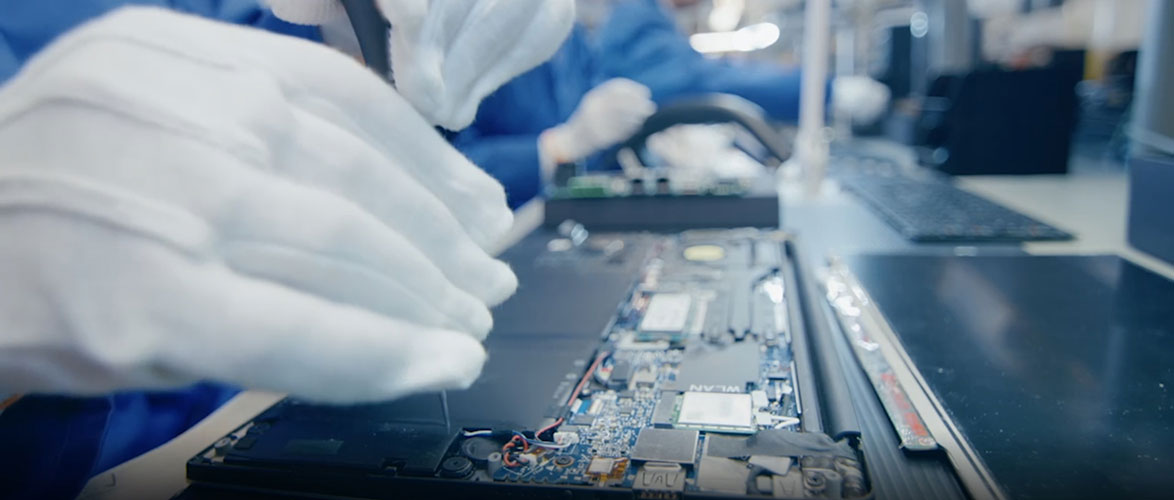

Manufacturing Engineering

DDG expertise in manufacturing engineering ensures that developed products get into production and once in production are produced as efficiently and as cost-effectively as possible.

Manufacturing engineering involves planning the details of manufacturing including researching and specifying or guiding development of tools, processes, machines and equipment. Manufacturing engineering ensures that production facilities and systems are arranged and ready for producing quality products with the least amount of NRE and capital expenditures. Manufacturing engineering at DDG also encompasses production engineering, process engineering and quality engineering functions.

DDG has relationships with a variety of Contract Manufacturers (CMs) that can be engaged to produce a client’s product. Manufacturing Engineering leads the effort to evaluate potential CMs. The CM selection process is typically performed as early in the development process as possible, as soon as a Product Specification is completed.

Manufacturing EngineeringServices

- Six Sigma process improvement

- Process FMEAs

- QS-9000 standards and requirements

- Lean manufacturing

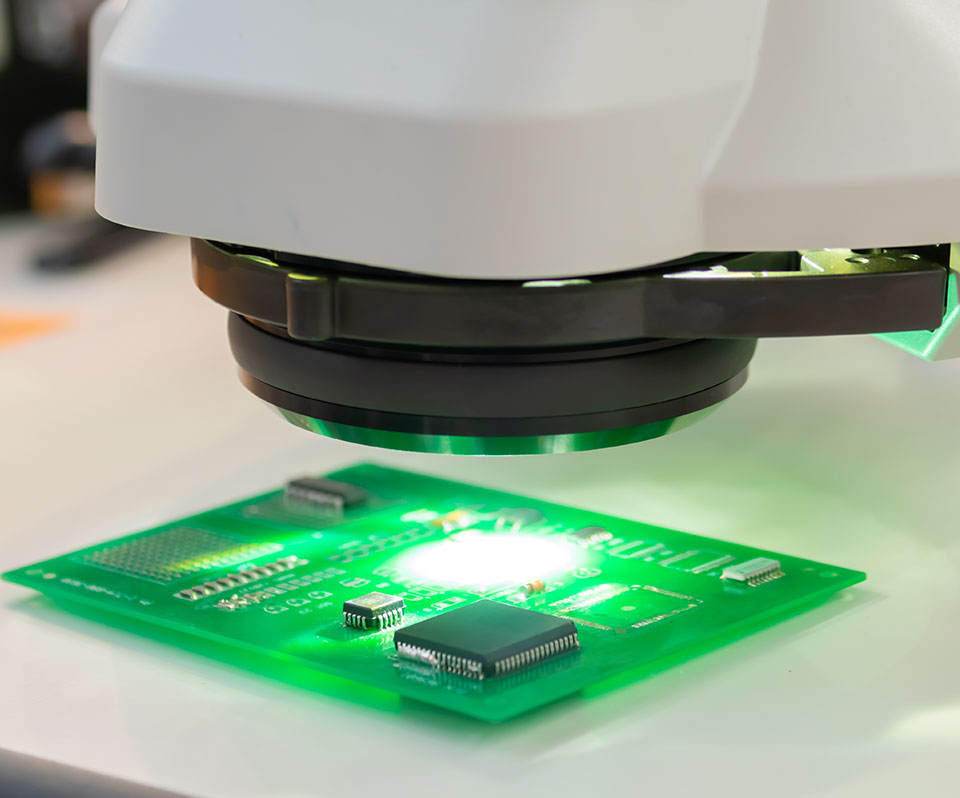

- Class 1000 and Class 10,000 cleanroom protocols

- Automated and manual assembly

- Ergonomic factors in assembly processes

- Manufacturing fixtures

- Product improvements for manufacturability

- Quality and manufacturing documentation

- Production personnel relations

After a product is successfully in first production, at client’s option, DDG manufacturing engineering may then be engaged to stay involved with the production of the client’s product on an ongoing basis. This has several advantages for the client, including continuity and the opportunity to implement and oversee a continuous improvement and cost-down program.